Insulating underlays for laminate and parquet

Insulation and underlays for laminate protect against moisture, ensure minimised footfall sound and compensate for unevenness in the subfloor. It is thus highly recommended to use an insulating underlay before laying a laminate floor. At LOGOCLIC® you will find various underlays and insulation for laminate with different properties – LOGOCLIC® offers a suitable product depending on individual requirements.

Make sure you have the right underlay

Before you lay laminate, find out about the necessary accessories. It is important to choose the right insulation and underlay for laminate. Depending on the subfloor or the nature of the floor, you may need insulation that compensates for possible unevenness and also acts as a vapour barrier. If you use underfloor heating, you should choose an underlay for laminate that is suitable for this type of heating and has good values in terms of thermal resistance. LOGOCLIC® also has suitable solutions to prevent impact sound and footfall sound.

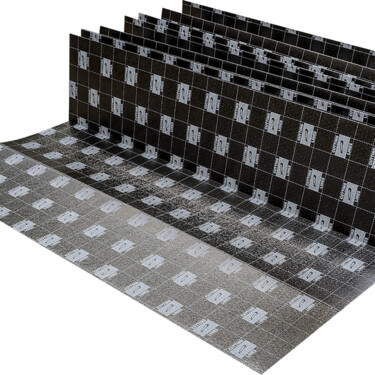

Insulation materials for laminate

Materials such as polymer, polyurethane foam, wood fibre, natural cork or XPS form the basis for your laminate flooring. The Pro Acoustic + insulating underlay, for example, consisting of visco-elastic polymers with an aluminium coating, is a true all-rounder: it acts as a vapour retarder, evens out critical substrates and reduces footfall sound. Insulation and underlays made of cork or wood fibre are particularly environmentally friendly and easy to recycle.

Find out more about the versatile LOGOCLIC® product range and choose a product that suits your requirements. The shopping planner helps you to buy all the necessary utensils for your project – so you don't forget anything!

Why a vapour barrier?

A vapour barrier or vapour retarder is used in the building industry to prevent water vapour from precipitating as condensation in the thermal insulation or flooring. In the laminate flooring sector, the vapour barrier is a film that is usually made of polyethylene (PE film). It prevents moisture from penetrating through the subfloor into the laminate flooring.

We have chosen an insulating underlay that is already equipped with an aluminium foil as a vapour barrier. Is the underlay laid with the silver layer facing upwards or downwards?

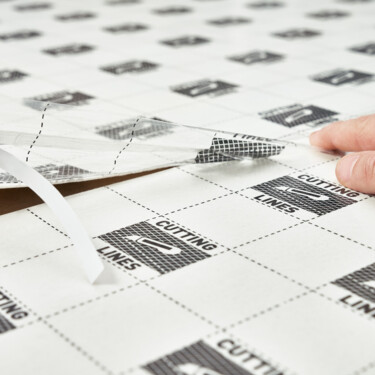

The underlay is laid with the coated side facing upwards. Lay the underlay with the aluminium coating slightly overlapping and glue the joints with aluminium adhesive tape. Some of the aluminium underlays already have an integrated adhesive surface.

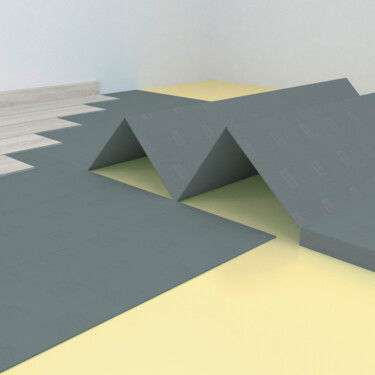

How do I reduce the walking noise of laminate flooring?

Laminate flooring is made up of individual panels. This can cause noise when you walk on it. The subfloor under the laminate floor also plays a role. To reduce the walking noise on the floor covering, there is no alternative to impact sound insulation. But you have two options here:

- Impact sound insulation as an underlay: Reduce footfall sound by laying an underlay under the laminate flooring. This minimises noise in the room – your neighbours will be grateful too. You will find various types of impact sound insulation in the LOGOCLIC® range.

- Integrated impact sound insulation: The Ambienta product line, for example, impresses with its integrated impact sound insulation. This means that no additional work step is required for impact sound installation when laying laminate. The laminate ideally dampens walking noises thanks to this integrated insulation.

Which is the best insulating underlay to use with underfloor heating?

If laminate flooring is to be laid over underfloor heating, the heat dissipation must be taken into account. If the floor covering insulates too much, the heat of the underfloor heating will be insufficiently used – thus a lot of energy will be lost.

The following reference values should be observed if insulating underlay is to be used with underfloor heating: the total thermal resistance should not exceed 0.15 m2K/W.

When do I need a vapour barrier film?

A vapour barrier is a PE film which protects the laminate from moisture. Because this film prevents moisture rising into the laminate flooring. If moisture were to penetrate the laminate floor, it would lead to swelling and rippling in the floor covering. You will find various types of vapour barrier films in the LOGOCLIC® range.

Take a look at the laminate insulation.

Which floors are particularly silent?

The laminate Silentos has an integrated impact sound insulation. For the laminate flooring Family you need to lay an insulation carpet pad. This is also done quite easily thanks to integrated adhesive strips.